CIL

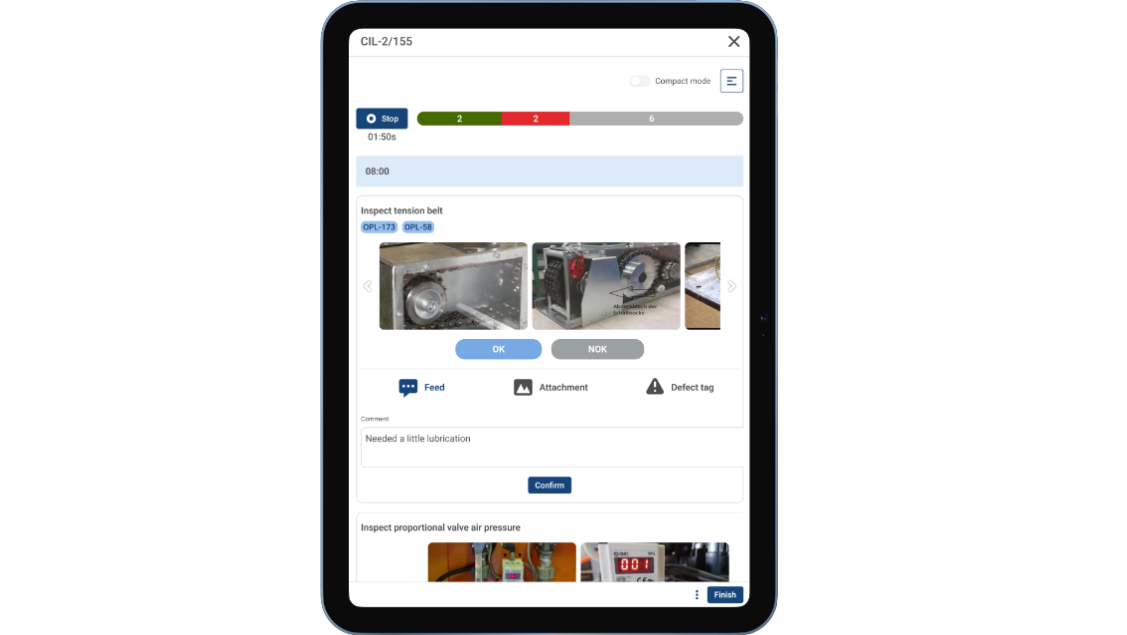

Allows users to create and execute Cleaning, Inspection and Lubrication plans (CIL) defining the standards to be checked. During the CIL process evidences like photo/video/comments can be inputted to the record and defect tags can also be created when a defect is found. The system is connected to the “OPL” (One Point Lesson) system so that an instruction can be linked to each inspection. The tool allows an approver to be assigned for the checklist if required and the configuration of notifications if a deviation is found.

Key Functionalities

- Configuration of scripts/templates

- Upload documents/OPL as standard for each point

- Photo/Video upload

- Defect Tag creation

- Email notifications/alerts

- Versioning control

- Database with CIL historical data

- Automatic reports

Impact

- Standardisation (e.g., forms, inspection tasks)

- Elimination of NVAA to generate reports and to find related inspections

- Control and traceability of inspections – tracking of compliance, duration and downtimes

- Reduction of equipment failures/breakdowns

- Cost reduction with paper forms (printing)